Static Chassis Manufacture

The B17 Steam Locomotive Trust (B17 SLT) is pleased to be able to report significant progress on the assembly of the static frame at Llangollen Railway Engineering Services. All the cast and fabricated frame stays have been delivered to Llangollen and started to be assembled as shown by the photographs below taken at the workshops in early June.

Independent Assessment

The Trust has also contracted with a new rail industry approved independent assessor, Ricardo Rail of Derby. Ricardo Rail has carried out an initial audit at Llangollen Railway Engineering Services of both the B17 SLT engineering management and design processes, along with the Llangollen Railway Engineering Services manufacturing processes and competencies. The audit was agreed as being successful, giving the Trust confidence in the way that we conduct our design and manufacturing activities and to continue in the same way for the rest of the project.

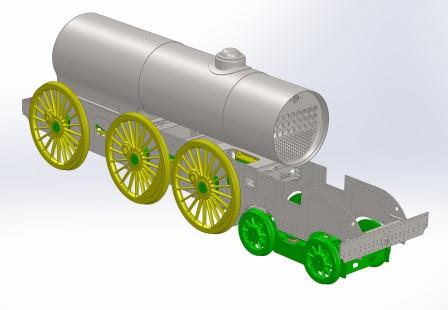

Rolling Chassis

Design work is well underway on the sub-assemblies and components that are required to progress the static chassis to a rolling chassis. Currently the detail design is being created for the manufacture of the wheels, roller bearings and axles including the necessary 21st century improvements for reliability and maintainability over the working life and duty cycles that will be required. Owing to the peculiarities of a B17 rolling chassis layout, each axle requires a different design for the pair of hornblocks. There is a level of commonality with other LNER new builds that provides the confidence in these necessary design improvements.

Boiler Design

A Defining Specification for the boiler has been created and discussions are being held with potential manufacturers to create a detail design and to obtain indicative costs.

East Anglian Manufacturing

The Trust has been successful to date in meeting its objective of placing contract with UK manufacturing companies and facilities wherever possible. However, to achieve meant that it is dependent on their being companies in the UK having the necessary new build steam experience or the physical capacity to create heavy engineered parts. Going forward many of the components to complete the rolling chassis and design and manufacture the boiler and firebox will also fall into this category of specialist capability and/or heavy engineering capacity.

To more align the B17 SLT project with its East Anglian heartland, the B17 SLT management team are now exploring the possibility of using manufacturers based in the B17 East Anglia area for more general engineering design and manufacture requirements.

If any reader knows of any East Anglian based engineering establishments that may have the necessary experience and capability for casting, forging, machining and fabrication/welding techniques for detail parts or restoration of existing large fabricated rail vehicles please contact the Trust. Typical examples of suitable components could be the chimney casting and the machining of the whistle.